|

|

|

|

The following page was printed from RemoteCentral.com:

| Topic: | Rack wiring "refinement" This thread has 39 replies. Displaying posts 1 through 15. |

|

| Post 1 made on Saturday June 20, 2009 at 04:40 |

Jimmy Bellagio Advanced Member |

Joined:

Posts: | January 2008

854 |

|

|

A couple of the guys need some refinement in the rack wiring area. Anyone know of any good resources, tips, or any other information that would be helpful in sharpening skills when it comes to rack wiring? Lately getting a lot of jobs just to rewire racks and I am not entirely pleased with the results. Looking for basics like what type of ties, how to seperate, steps by order, etc.

Any help would be greatly appreciated, obviously some of you have incredible skills in this area.

Thanks- Jimmy

|

James S. Bellagio |

|

| Post 2 made on Saturday June 20, 2009 at 11:26 |

Ernie Bornn-Gilman Yes, That Ernie! |

Joined:

Posts: | December 2001

30,104 |

|

|

There have been a few threads here about this. Back when "What did you do today" was only a few pages, there were some shots of excellent racks. I suppose the hardest part of finding them will be figuring out just what to search for.

|

A good answer is easier with a clear question giving the make and model of everything.

"The biggest problem in communication is the illusion that it has taken place." -- G. “Bernie” Shaw |

|

| Post 3 made on Saturday June 20, 2009 at 12:23 |

proaudio95 Advanced Member |

Joined:

Posts: | January 2008

936 |

|

|

IMO, wiring a rack is equal parts experience, training, and art. you can have them read industry mags for visual help, trade shows help too. to be completely honest, as harsh as it may sound, your brutal honesty may be the best eye opener to what they are doing "wrong". in their eyes, their artwork may be great, but we would all be using harmony remotes had someone not shown us the error of our ways and what else was available out there. some guys will always be bad at wiring racks, it takes a level of creativity that some just dont have. but those same guys maybe your best wiring and installation guys.

good luck

proaudio

|

Steven Brawner ISF, HAA, Lutron, CEDIA certified ProAudio GA www.ProAudioGA.com |

|

| Post 4 made on Saturday June 20, 2009 at 12:25 |

alihashemi Select Member |

Joined:

Posts: | June 2006

1,891 |

|

|

[Link: remotecentral.com]Take a look at that thread. There is a great amount of advice in the thread and it also includes a shot at a brilliantly done rack by Simoneales.

|

Ali Hashemi |

|

| OP | Post 5 made on Saturday June 20, 2009 at 14:50 |

Jimmy Bellagio Advanced Member |

Joined:

Posts: | January 2008

854 |

|

|

I appreciate it guys, obviously wiring a rack is not going to be learned by reading a book - (like my golf game) - experience of course is the key, but I am just looking for some rules of thumb, helpful hint, what to do first, what to save for last, how to seperate, etc. Thanks again. Jim

|

James S. Bellagio |

|

| Post 6 made on Saturday June 20, 2009 at 15:53 |

39 Cent Stamp Elite Member |

Joined:

Posts: | May 2007

17,518 |

|

|

Some pics would be helpful. Advice for a freestanding rack will be (completely) different from a slide out rack. A rack with wheels will be similar to a free standing rack with one exception. You have to have slack to get the rack in and out in a roll out rack. Freestanding Rack Tips Racks should be planned during construction. You should know exactly where the rack will be before you pull a single wire. Plan the ceiling out so you have space (and access to the space) to hide a service loop. Service loops may never be used and may seem like a waste but in ten years or 2.. if the client decides to upgrade your cables will be long enough to reach anything in the rack. That means an old ethernet jack in the extra bedroom can now deliver video to a TV. Avoid using Knock down racks like the slim5 if you can. These racks leave you ZERO space to manage cable. Same with the slide outs and slide out twisters. If you can get away with not using them.. DONT USE THEM! The best case scenario is a free standing rack thats positioned so you have the ability to walk behind them. These racks are super easy to work with and that means your guys wont get tired of straddling the slide out racks or fighting the cables in the twister racks and they will have plenty of space to manage cable up the back rails. Plan for more rack space than you need. No matter what you do you will end up adding 5 to 10 rack spaces of gear at the end of the job. I cant tell you how many times i have seen AV Receivers sitting on their sides in closets or a stack of 4+ cable boxes sitting on one rack shelf because theres isnt room to use custom shelves. Use custom length cables and dont leave unused cables hanging out in the rack or excess length along the sides. Custom length cables take longer and cost more but they leave zero mess and clutter. As long as your guys have connectors you wont ever run into a situation where your raping the directv boxes looking for component cables to finish up the install. Use mini 23 guage coax for interconnects. Especially if your sending audio and video from the head end to the room end vs using baluns. The bulk of RG6 and even RG59 will fill your rack up very quick and make it impossible to manage. Power strips. Make sure your guys have enough power strips/surge protectors UPS etc. This is often overlooked until the end of the job when you realize that every damn device in the rack has a walwart power supply that takes up three outlets instead of 1. I prefer horizontal power strips because they mount at the front of the rack and dont take up space along the back rails. Others prefer the vertical power strips because it puts an outlet behind each device. Choose your poison. Schematics, rack drawings. Have the rack laid out before they begin and schematics for how everything wires up. Making decisions on where the AMP should go is easier to do sitting at a desk vs in a dimly lit basement with 20 guys trying to finish up work that the GC claimed was already done. I literally had guys climbing thru my racks @ an install once. The contractors were supposed to schedule me when the basement was completed. When i got there i sat on my hands for 3 days while they finished the basement and painted and installed tile. When i finally started work i had 2 ganged racks that i had to swing out into the hall blocking the stairs. After the 5th time of rolling them out of the way i decided i wasnt going to move them anymore and they could climb in the window.. thats when they started trying to climb thru the rack. I mounted a couple of components to block access and played the @sshole all day telling them to go around. If that rack wasnt on paper it would have looked like hell because i was real tired of being there. The less time your guys spend thinking about how something should be wired the better. The faster their job goes the more time they have to make it pretty. Finally... Try to eliminate types of wire you use. The racks im working on today have.. 14/4 Cat5e Cat6 Cresnet RG6 23 guage mini coax And thats it. We use Cat5 for everything we possibly can including IR and RS-232. Patching all of the cables in the house keeps the racks nice and tidy. The only cables that will be added are ones that are actually being used. All of the spare cables are not dangling down the rack. Speaker cable goes straight to the amps. Done and out of the way. Cresnet goes to the C2N-HBLOCKS. Done and out of the way. Cat & RG6 go to patch panels across the back of the rack. Done out of the way. The 23 guage is used for interconnects. Cat5/RG6 and Cresnet are terminated right at the top of the rack so they don't interfere with anything else. An example of terminating every cat5 in the house to patch panels.  An example of Cresnet being terminated at the top of the rack.  An example of taking speaker cable straight down to the amps and cutting it to length. Also see how using the mini coax for interconnects uses up less space across the lacer bars.  Even if the guys dont have time to make bundles perfectly neat they can still have a nice looking rack. Heres a pic of a rack i did 6 or so years ago. None of the bundles are particularly neat but because i have them seperated and following lines they look pretty good.

|

Avid Stamp Collector - I really love 39 Cent Stamps |

|

| Post 7 made on Saturday June 20, 2009 at 15:54 |

Oz AVI Senior Member |

Joined:

Posts: | November 2004

1,151 |

|

|

Jimmy, two things that may help, firstly, as mentioned in Simons' thread, Velco is your friend.

Second, from the exit point on the wall, drop the cable to the floor, then cut it at ceiling height. This will ensure plenty of working length.

Iain

|

|

| Post 8 made on Saturday June 20, 2009 at 15:59 |

39 Cent Stamp Elite Member |

Joined:

Posts: | May 2007

17,518 |

|

|

On June 20, 2009 at 15:54, Oz AVI said...

Jimmy, two things that may help, firstly, as mentioned in Simons' thread, Velco is your friend.

Second, from the exit point on the wall, drop the cable to the floor, then cut it at ceiling height. This will ensure plenty of working length.

Iain I do that to. Before i start wiring the racks i unravel the bundles and clean off the cables and cut them all to a specific length. Makes them much easier to deal with from that point on.

|

Avid Stamp Collector - I really love 39 Cent Stamps |

|

| Post 9 made on Saturday June 20, 2009 at 23:27 |

proaudio95 Advanced Member |

Joined:

Posts: | January 2008

936 |

|

|

IMO, that post by 39 cent stamp should be permanently locked and put on the main forum page. that is possibly the best explaination and examples of quality wiring techniques i have ever heard. no matter how much we may agree and want to say the same thing, you have done it and done it well.

thank you for the post!!

proaudio

|

Steven Brawner ISF, HAA, Lutron, CEDIA certified ProAudio GA www.ProAudioGA.com |

|

| Post 10 made on Sunday June 21, 2009 at 01:25 |

FreddyFreeloader Super Member |

Joined:

Posts: | April 2004

3,243 |

|

|

You came to the right place for amazing pics and advice. We know your guys have the skills and knowledge (pics and advice,) or you wouldn't have hired them. We can only hope that your guys have the 3rd most important element to this equation: desire.

|

|

| Post 11 made on Monday February 1, 2010 at 19:59 |

sofa_king_CI Super Member |

Joined:

Posts: | June 2009

4,230 |

|

|

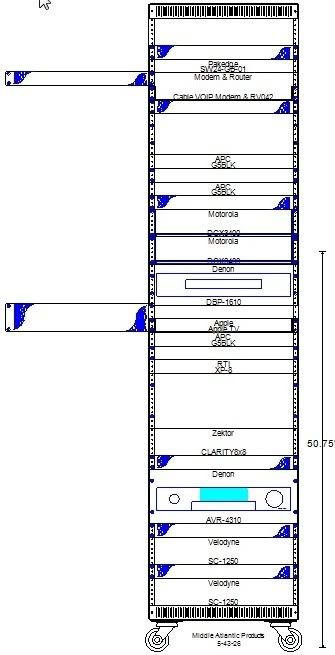

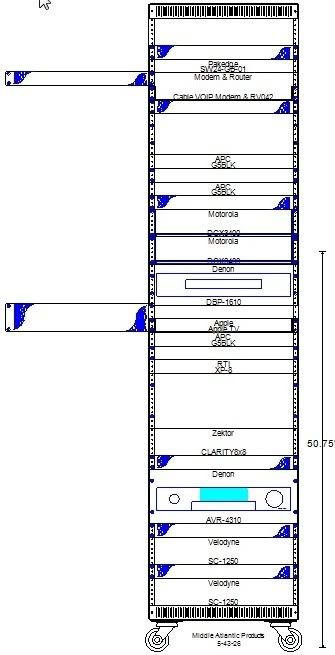

I would like to further this discussion. Stamp, are you punching down ALL cat5 into the patch panels (even that used for baluns, control, whatever besides data)? How do you guys deal with IR emitters. I'm thinking about running male-female cables from the control system to each piece of equipment or using something like this at each shelf.  In a rack that I will be doing this week, I have all my cables coming down from the ceiling, but the rack has to be on casters (in a closet). At the very top of the rack I have the network gear, including a 24 port switch. I've gone back and forth and whether or not to use a patch panel. Really the cables will come down to the rack and be right where the switch is so I don't really see the point of a patch panel for these. Doing the patch panel at the back of the rack, definitely takes up a lot of space in the front that can't really be used anymore, in some cases, it could be half the rack, but then I guess you should just add a 2nd rack to the system. I guess I usually have some fans at the very top anyway for some of the space. Here's my plan. The mesh vented panels that are to the left of the rack will actually go on in front of the equipment that it is next, for example the AppleTV will be concealed behind this panel. I may put the router and modem behind as well, but currently they aren't, its just showing as 2U when they are only 1U. The network will all be on the top APC G5BLK so that the client can just hit a single button to reboot the entire network.

|

do wino hue? |

|

| Post 12 made on Monday February 1, 2010 at 20:22 |

39 Cent Stamp Elite Member |

Joined:

Posts: | May 2007

17,518 |

|

|

On February 1, 2010 at 19:59, sofa_king_CI said...

I would like to further this discussion.

Stamp, are you punching down ALL cat5 into the patch panels (even that used for baluns, control, whatever besides data)? Every Cat5/Cat6 cable in the house is punched down to patch panels that are mounted to the rear rails in the rack. Phone/Data/Audio/Video/Control. The key to making this work and not end up as a breakout cable nightmare is to pull a single Cat5 for each thing. Dont try and use 1 cat5 for a phone, a serial cable and a contact closure for a shade. How do you guys deal with IR emitters. I'm thinking about running male-female cables from the control system to each piece of equipment or using something like this at each shelf. This is what i am using now on each component. I put the emitters inside and mount this block right to the back of it. It would work equally as well surface mounted in the front bezel.  In the rack i use a 12' mono 1/8" patch cable to connect it to the processor. I cut it to length (crestron has phoenix connectors at the processor for IR). I havent had to use Cat5 to extend an emitter in a while because i usually have a CNXRMC or a local processor for IR. I assume you could use the keystone jack there to extend the emitter in the same way.  In a rack that I will be doing this week, I have all my cables coming down from the ceiling, but the rack has to be on casters (in a closet). At the very top of the rack I have the network gear, including a 24 port switch. I've gone back and forth and whether or not to use a patch panel. Really the cables will come down to the rack and be right where the switch is so I don't really see the point of a patch panel for these. The patch panel will do a couple things. #1. All cables are punched down and this makes them easy to locate and test quickly. #2. Making a specific cable do something different on the fly is very easy. A 6' patch cable can make a ethernet jack be a component balun in minutes or in 2 years when you go back for upgrades. The idea behind the patch panel is that the cat5's in the house are just extension cables from the rack patch panel to the wallplate at the other end. They are permanently part of the house now (so is the rack). Your AV & automation gear patches to these jacks. You go to a bedroom and pull a phone and make it a component balun or an ethernet jack. Or you gut the old system for a complete upgrade. The only cables you have to remove are the patch cables. Doing the patch panel at the back of the rack, definitely takes up a lot of space in the front that can't really be used anymore, in some cases, it could be half the rack, but then I guess you should just add a 2nd rack to the system. I guess I usually have some fans at the very top anyway for some of the space. We put monitors or devices that dont require rear access. You dont want to seal off access to something with the patch panels because you will kick yourself all day long. Its better to skip the patch panels if you dont have space then to try and fight it the whole time. Here's my plan. The mesh vented panels that are to the left of the rack will actually go on in front of the equipment that it is next, for example the AppleTV will be concealed behind this panel. I may put the router and modem behind as well, but currently they aren't, its just showing as 2U when they are only 1U. The network will all be on the top APC G5BLK so that the client can just hit a single button to reboot the entire network.  Just make sure the phone/cable/sat guy can get to their boxes without trashing your rack. You would be suprised how many people cant take a couple of screws out of a rack plate... and how many dont get that if your pulling a cable and it gets tight... that doesnt mean pull harder.

|

Avid Stamp Collector - I really love 39 Cent Stamps |

|

| Post 13 made on Monday February 1, 2010 at 20:31 |

sofa_king_CI Super Member |

Joined:

Posts: | June 2009

4,230 |

|

|

How many guys bury emitters in equipment, specifically CBL/SAT boxes?

We don't, and for those that don't, what do you use to cover your emitters? Niles comes with (or at least used to, not sure if they still do) a little emitter cover, but they aren't in the catalog for regular purchase.

|

do wino hue? |

|

| Post 14 made on Monday February 1, 2010 at 20:36 |

39 Cent Stamp Elite Member |

Joined:

Posts: | May 2007

17,518 |

|

|

I was only putting them in DirecTV boxes until recently. I bought the security bits to get inside of cable boxes.

|

Avid Stamp Collector - I really love 39 Cent Stamps |

|

| Post 15 made on Tuesday February 2, 2010 at 01:20 |

Neurorad Super Member |

Joined:

Posts: | September 2007

3,011 |

|

|

Stamp, thanks so much for sharing. :)

Maybe MA will throw you a bone to produce a 'white paper'. ;)

|

TB A+ Partner

Believe nothing, no matter where you read it, or who said it, no matter if I have said it, unless it agrees with your own reason and your own common sense. -Buddha |

|

|

Before you can reply to a message... |

You must first register for a Remote Central user account - it's fast and free! Or, if you already have an account, please login now. |

Please read the following: Unsolicited commercial advertisements are absolutely not permitted on this forum. Other private buy & sell messages should be posted to our Marketplace. For information on how to advertise your service or product click here. Remote Central reserves the right to remove or modify any post that is deemed inappropriate.

|

|