|

|

|

|

The following page was printed from RemoteCentral.com:

| Topic: | Managing Pre-wiring at the Head-end This thread has 31 replies. Displaying posts 16 through 30. |

|

| Post 16 made on Saturday October 14, 2017 at 15:00 |

kgossen Super Member |

Joined:

Posts: | March 2008

3,026 |

|

|

On October 14, 2017 at 14:31, 3PedalMINI said...

Ive tried the bags/shrinkwrap etc etc....doesnt ever work Has always worked for me. I buy the roll of vapor barrier plastic and wrap them tight. Never had a single issue.

|

"Quality isn't expensive, it's Priceless!" |

|

| Post 17 made on Saturday October 14, 2017 at 17:33 |

highfigh Loyal Member |

Joined:

Posts: | September 2004

8,321 |

|

|

I use a different color for the application- Data is blue, Voice is gray, AV over Cat5 is yellow and coax is black unless I need two and then, I add another feed in white. If I need multiple data in one room/area, I may use bundle if I also need coax and sometimes, I split the pairs. I also use a network switch for each AV system rack and bundle each group of cables when I pull them, so it's easy to label them 'Living Room East or West, Office, Master Bedroom, etc. That way, the colors tell me where the cables need to go and I separate them at the time of termination at the HE. I have used this color code for 20 years, so it's burned in. I label each individual cable when I separate them for bundling.

This method prevents me from spending a lot of time labeling when I have other things to do- I use shrink wrap if it needs to be protected.

|

My mechanic told me, "I couldn't repair your brakes, so I made your horn louder." |

|

| Post 18 made on Saturday October 14, 2017 at 17:50 |

buzz Super Member |

Joined:

Posts: | May 2003

4,371 |

|

|

I use color coded cables, keep the wire lengths generous, quickie identify each cable, group, and wrap for protection during construction. At the final trim out, I'll use printed labels. The extra wire length has saved me lots of trouble when I return to find that the alarm guy and the cable guy had been happy to occupy the space that I thought was mine.

|

|

| Post 19 made on Saturday October 14, 2017 at 18:30 |

Mac Burks (39) Elite Member |

Joined:

Posts: | May 2007

17,518 |

|

|

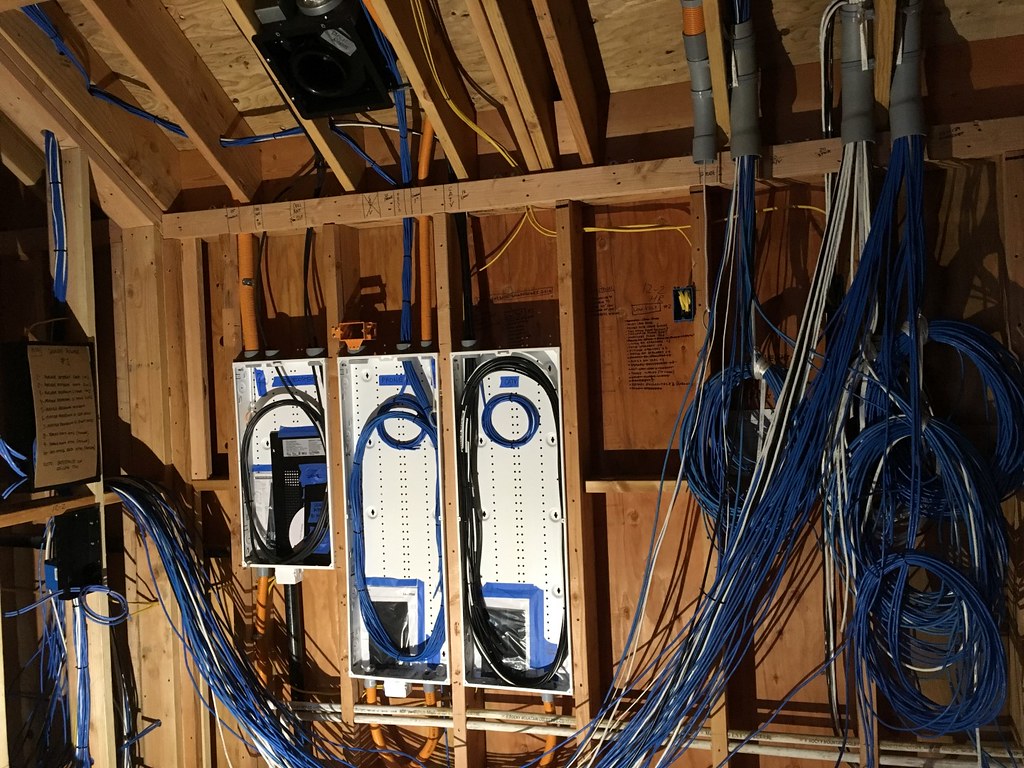

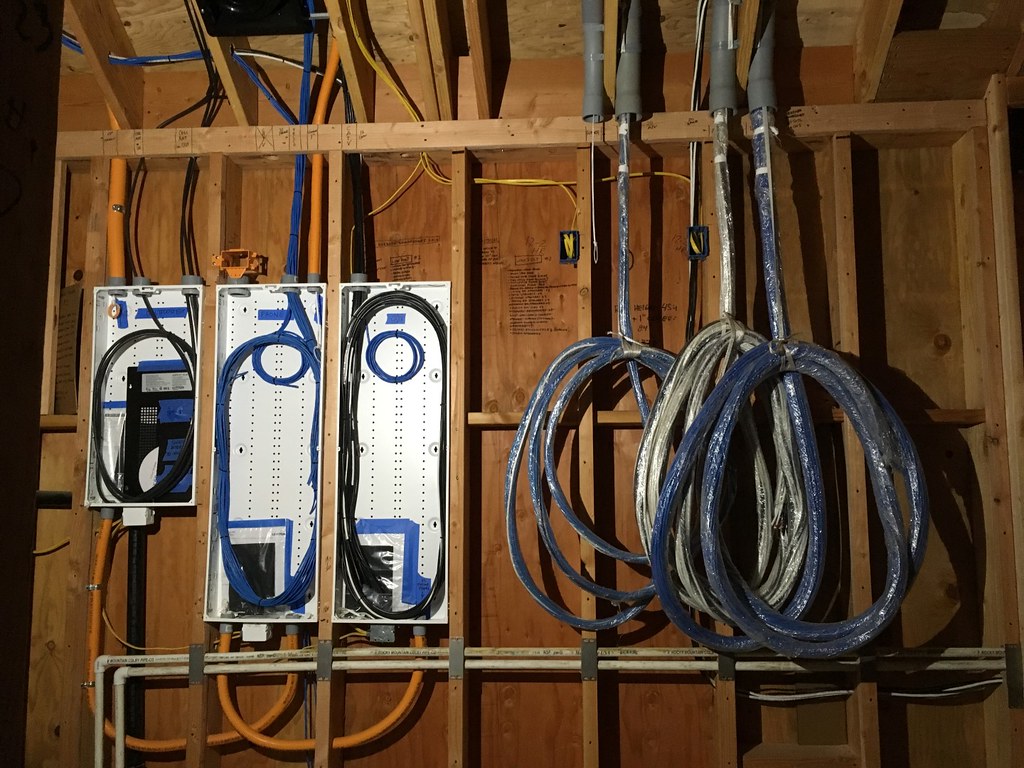

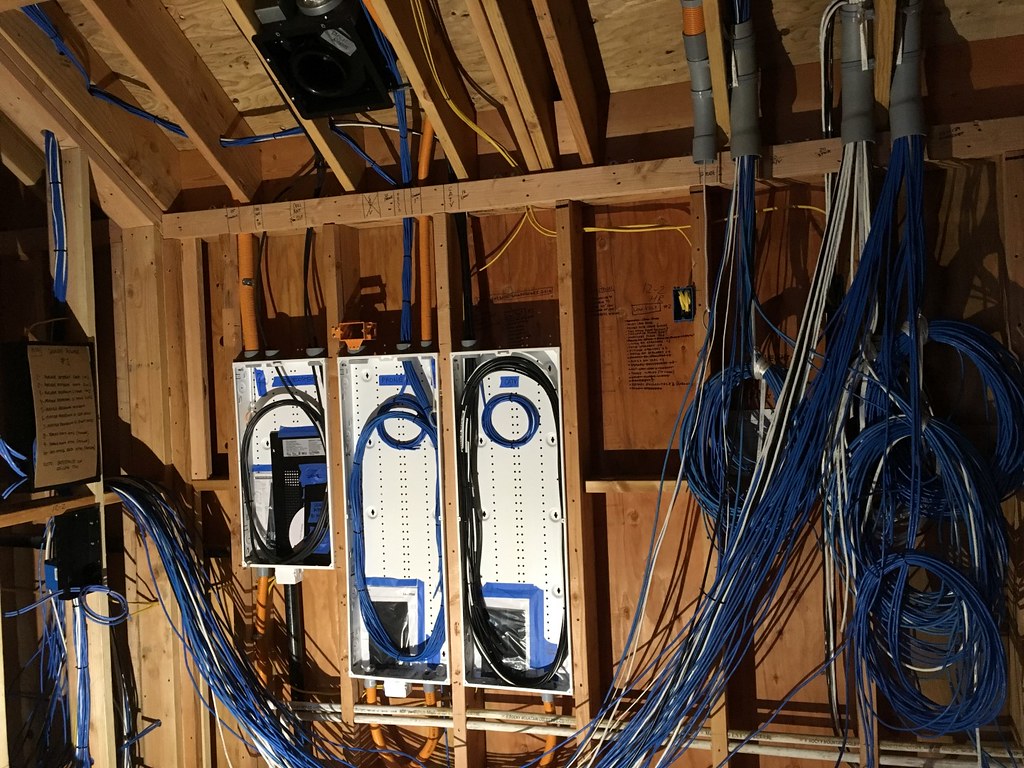

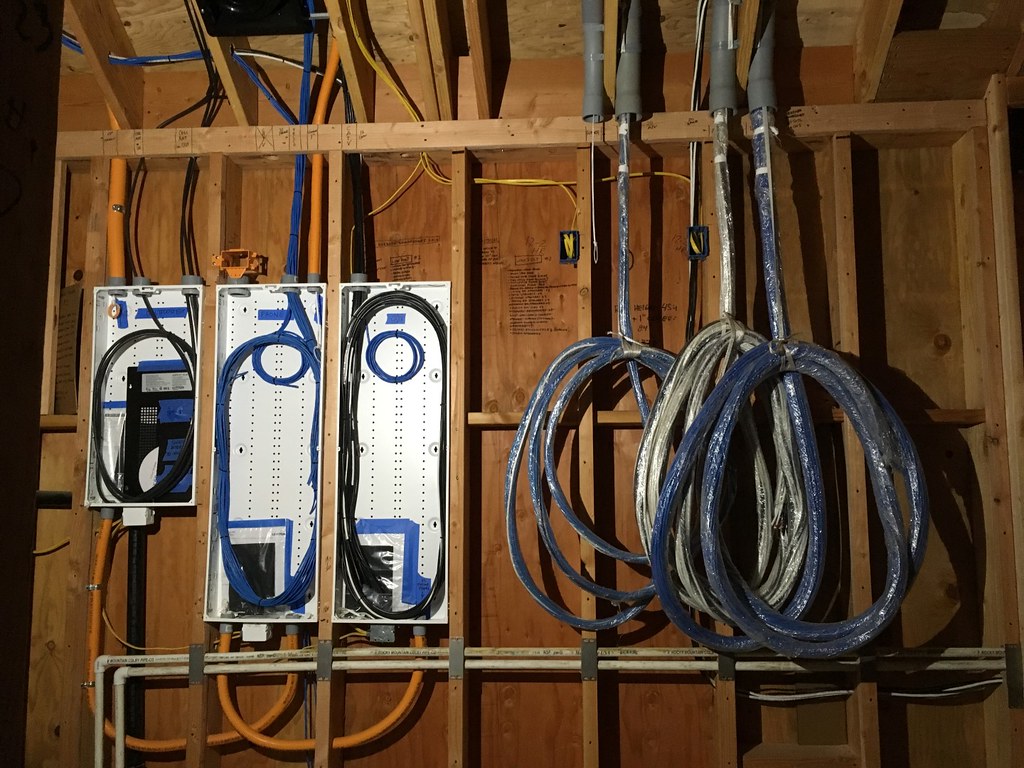

I'm not real clear about what you are asking but...if you are talking about managing the bundles of filthy taped up cables at the head end while trying to terminate and test cables...i do it this way. First thing i do is get all zip ties tape chunks of drywall mud off the wires and stretch them all out. Then i clean each cable with a microfiber and windex. Then i sort cables...speaker cable here cat 5 there so on and so forth. Then i neatly bundle and route cables to their locations. SO speaker cables to the rack where the amp goes...Cat5's for the security cameras to the location of the NVR....rinse repeat. Then i trim and relabel all cables leaving enough for a service loop and enough to get to anything in that rack. So usually like 10 feet once the bundle makes its way into the rack. Now everything is manageable. Its clean new label all the same length and you dont have to trip over cables because everything is bundled and routed. With Cat5's and RG6 i usually just randomly punch them down on patch panels. I don't worry abut trying to keep them in a specific order. My spreadsheet gets updated on the fly so i know whats where. Speaker cable and fiber are direct connections. Once everything is trimmed routed punched down its much easier to tone/test/verify. Before and after photos of a project. When we first arrived after sheetrock went up...  After a week of sorting and routing...

Last edited by Mac Burks (39) on October 14, 2017 19:30.

|

Avid Stamp Collector - I really love 39 Cent Stamps |

|

| Post 20 made on Saturday October 14, 2017 at 18:31 |

Mac Burks (39) Elite Member |

Joined:

Posts: | May 2007

17,518 |

|

|

On October 14, 2017 at 17:33, highfigh said...

I use a different color for the application- Data is blue, Voice is gray, AV over Cat5 is yellow and coax is black unless I need two and then, I add another feed in white. If I need multiple data in one room/area, I may use bundle if I also need coax and sometimes, I split the pairs. I also use a network switch for each AV system rack and bundle each group of cables when I pull them, so it's easy to label them 'Living Room East or West, Office, Master Bedroom, etc. That way, the colors tell me where the cables need to go and I separate them at the time of termination at the HE. I have used this color code for 20 years, so it's burned in. I label each individual cable when I separate them for bundling.

This method prevents me from spending a lot of time labeling when I have other things to do- I use shrink wrap if it needs to be protected. The color method is great and we do it often. The problem is it always breaks down towards the end when you have 500' of blue and zero feet of yellow and someone adds something that requires 1 more yellow cable and you just say...screw it use the blue.

|

Avid Stamp Collector - I really love 39 Cent Stamps |

|

| Post 21 made on Saturday October 14, 2017 at 19:26 |

highfigh Loyal Member |

Joined:

Posts: | September 2004

8,321 |

|

|

On October 14, 2017 at 18:31, Mac Burks (39) said...

The color method is great and we do it often. The problem is it always breaks down towards the end when you have 500' of blue and zero feet of yellow and someone adds something that requires 1 more yellow cable and you just say...screw it use the blue. True, but if the area/room's cables of each type are bundled, it's easier than if everything is in one big bundle. OTOH, everything has to go somewhere, so you could always leave the odd assignment till last and tone it. If everything has been toned, tested and labeled, the last one HAS TO be the one, right? One house I worked on has a Playroom in the basement and when I needed to extend those cables, I found a total of three- two Cat5e and one RG6. When I looked in the enclosure as I was trying to sort out the network problems on the 2nd floor, I found about 8 Cat5e in blue and gray, labeled as 'Playroom'. I checked for continuity to the basement from the various wall plates and found a total of only three or four cables that could be used- the rest showed as Open, Shorted or with my TDR, 'Out Of Range'. They used bundled coax/Cat5e for the 2nd floor runs and loose cabling for the basement. They had tried to run a bundle to the Kitchen and couldn't find the hole they must have drilled before the cabinets went in, so they gave up and left it hanging behind a door. I needed to run speaker and sub wiring to the adjacent dining room, so I drilled down from the cabinet at the rear corner and went down to find my push rod- didn't see it in the gaping hole they made in the basement ceiling, so I drilled a new one inch hole on the far side of the joist for the opening. Found it! They missed it by about 8 inches.

|

My mechanic told me, "I couldn't repair your brakes, so I made your horn louder." |

|

| OP | Post 22 made on Saturday October 14, 2017 at 19:54 |

crosen Senior Member |

Joined:

Posts: | April 2009

1,262 |

|

|

Thank you. This starts to get at my question. I wonder, though, about how to leave the wires right when they are pulled to minimize the mess that has to get untangled down the line. On October 14, 2017 at 18:30, Mac Burks (39) said...

I'm not real clear about what you are asking but...if you are talking about managing the bundles of filthy taped up cables at the head end while trying to terminate and test cables...i do it this way. First thing i do is get all zip ties tape chunks of drywall mud off the wires and stretch them all out. Then i clean each cable with a microfiber and windex. Then i sort cables...speaker cable here cat 5 there so on and so forth. Then i neatly bundle and route cables to their locations. SO speaker cables to the rack where the amp goes...Cat5's for the security cameras to the location of the NVR....rinse repeat. Then i trim and relabel all cables leaving enough for a service loop and enough to get to anything in that rack. So usually like 10 feet once the bundle makes its way into the rack. Now everything is manageable. Its clean new label all the same length and you dont have to trip over cables because everything is bundled and routed. With Cat5's and RG6 i usually just randomly punch them down on patch panels. I don't worry abut trying to keep them in a specific order. My spreadsheet gets updated on the fly so i know whats where. Speaker cable and fiber are direct connections. Once everything is trimmed routed punched down its much easier to tone/test/verify. Before and after photos of a project. When we first arrived after sheetrock went up...  After a week of sorting and routing...  |

If it's not simple, it's not sufficiently advanced. |

|

| Post 23 made on Saturday October 14, 2017 at 20:17 |

Ernie Gilman Yes, That Ernie! |

Joined:

Posts: | December 2001

30,104 |

|

|

On October 14, 2017 at 04:46, crosen said...

Wow, I had been clear on not toning through one pair of twisted wire, but the concept of using a power ground is totally new to me.

What's an example of a good power ground? The ground of a 120V outlet comes to mind, but that doesn't sound quite like a good idea! It's a good idea. Many of the alligator clips of tone generators can be forced into the ground socket of a 120V outlet. I do that all the time. Yesterday I located an RG-6 this way on a construction site. I connected to the nearest steel stud and to the shield of the cable. I've seen guys connect to the inside of an RG-6, not realizing that by doing so, they are minimizing the broadcasting of the signal. I've even just had a helper hold the ground lead. His whatever potential was so different from the wire that the signal went pretty well, for sure much better than when you attach to a pair of wires.

|

A good answer is easier with a clear question giving the make and model of everything.

"The biggest problem in communication is the illusion that it has taken place." -- G. “Bernie” Shaw |

|

| Post 24 made on Saturday October 14, 2017 at 21:58 |

Mac Burks (39) Elite Member |

Joined:

Posts: | May 2007

17,518 |

|

|

On October 14, 2017 at 19:54, crosen said...

Thank you. This starts to get at my question. I wonder, though, about how to leave the wires right when they are pulled to minimize the mess that has to get untangled down the line. The only thing i have seen that sort of works is to mount enclosures for each type of cable on the back wall. At the head end ceiling or wall where the wire comes in you sort bundles and route cables to their specified enclosure. So Cat5's to one can, RG6 to another, Speaker to another fiber to another and so on and so forth. When you are done wiring roll up your bundles and close the door and wait for trim out. Dont forget to deal with getting wire from enclosure to racks. I would install 4" or 3" pipe between the enclosures and from the enclosures to the racks.

|

Avid Stamp Collector - I really love 39 Cent Stamps |

|

| Post 25 made on Saturday October 14, 2017 at 23:03 |

SB Smarthomes Super Member |

Joined:

Posts: | July 2007

2,634 |

|

|

I spend the time during rough-in to make sure all the cables are organized and cut to length and labeled. During rough-in I normally just label all the wires at both ends with a sharpie and save the labels for trim-out. Here's a few photo's of an equipment room during rough-in and then prepared for drywall and paint. I always wrap all the bundles in shrink wrap which protects them, preserves the labels and doesn't require any zip ties or electrical tape that will have to be removed later. As a one-man shop I can't imagine how long it would take to sort out and tone wires that weren't properly prepped during the pre-wire.  [/img]  [/img]  [/img]

|

www.sbsmarthomes.comSanta Barbara Smarthomes |

|

| OP | Post 26 made on Saturday October 14, 2017 at 23:59 |

crosen Senior Member |

Joined:

Posts: | April 2009

1,262 |

|

|

Very nice! On October 14, 2017 at 23:03, SB Smarthomes said...

I spend the time during rough-in to make sure all the cables are organized and cut to length and labeled. During rough-in I normally just label all the wires at both ends with a sharpie and save the labels for trim-out. Here's a few photo's of an equipment room during rough-in and then prepared for drywall and paint. I always wrap all the bundles in shrink wrap which protects them, preserves the labels and doesn't require any zip ties or electrical tape that will have to be removed later. As a one-man shop I can't imagine how long it would take to sort out and tone wires that weren't properly prepped during the pre-wire.  [/img]  [/img]  [/img] |

If it's not simple, it's not sufficiently advanced. |

|

| Post 27 made on Sunday October 15, 2017 at 12:03 |

Mac Burks (39) Elite Member |

Joined:

Posts: | May 2007

17,518 |

|

|

On October 14, 2017 at 23:59, crosen said...

Very nice! SB's photos are great and exactly what i was trying to describe.

|

Avid Stamp Collector - I really love 39 Cent Stamps |

|

| Post 28 made on Thursday October 19, 2017 at 17:22 |

77W Advanced Member |

Joined:

Posts: | June 2012

971 |

|

|

On October 14, 2017 at 11:04, Rob Grabon said...

Use multiple rolls of colored electrical tape to color code your wires.

For instance, all outdoor wires get a green band, bedrooms yellow, family media type rooms red, etc.

Then from even 10' away you can narrow 50 cables down to probably 3 and check their printed labels.

Even after trim and connection, looking at the back of a switch, you'll have maybe 4 with red bands to check closer, rather than reviewing 24. Gonna start doing this for some larger rough ins where we have a ton ton ton of wire.

|

|

| Post 29 made on Thursday October 19, 2017 at 17:23 |

77W Advanced Member |

Joined:

Posts: | June 2012

971 |

|

|

On October 14, 2017 at 08:22, buzz said...

I like my Fluke. I once volunteered to help a friend move into an office building. The rooms were sort of prewired with phone jacks, but in one case I needed to bridge two jacks that were home runs to the basement. No big deal, I thought, until I got to the basement facing a densely packed 7'x9' array of 66 blocks. It turned out not to be a big deal because I found each pair in about a minute.

With the Fluke tool, you can positively identify a pair by using the wire map feature because it only responds to conduction. I've had one of these for close to 10 years now probably....and I still don't know how to use the wire map feature. I guess I'll RTFM.

|

|

| Post 30 made on Friday October 20, 2017 at 05:00 |

theremoteteam Lurking Member |

|

|

Be careful tho. Was trying to find buried spkr wires and uncovered romex before

|

|

|

Before you can reply to a message... |

You must first register for a Remote Central user account - it's fast and free! Or, if you already have an account, please login now. |

Please read the following: Unsolicited commercial advertisements are absolutely not permitted on this forum. Other private buy & sell messages should be posted to our Marketplace. For information on how to advertise your service or product click here. Remote Central reserves the right to remove or modify any post that is deemed inappropriate.

|

|